This was a typical example of a well used pipe. The rim had a chip taken out from repeated tapping it on a hard surface. Thick lava covered the rest of the rim and the rock hard cake was very thick. The main challenge was the original stem had a fingernail size broken off at the bit. The opening was so large, exposing the entire airway, it had me wanting to try my hand at replacing a whole section instead of my usual patching holes and rebuilding bits.

I found a damaged donor stem and took a pic side by side, feeling like Dr. Frankenstein.

I used a cutting wheel on my dremel and cut out a section pretty close to what I needed. Here it is upside down so you can see the funnel area.

A little filing and it fit the area, I wanted the edge of the bit to line up on the stem side, not worrying about it protruding on the other side.

I put a pipe cleaner wrapped in clear tape in the airway, charcoal and black CA glue to seal it in.

After drying, I filed and sanded and touched up the button end and some micro bubbles that always seem to pop up. More sanding and buffing and it has a smooth mirror shine. But against the light you can see the repaired area. I went back already and reworked some of the areas but I’m still not happy with the result.

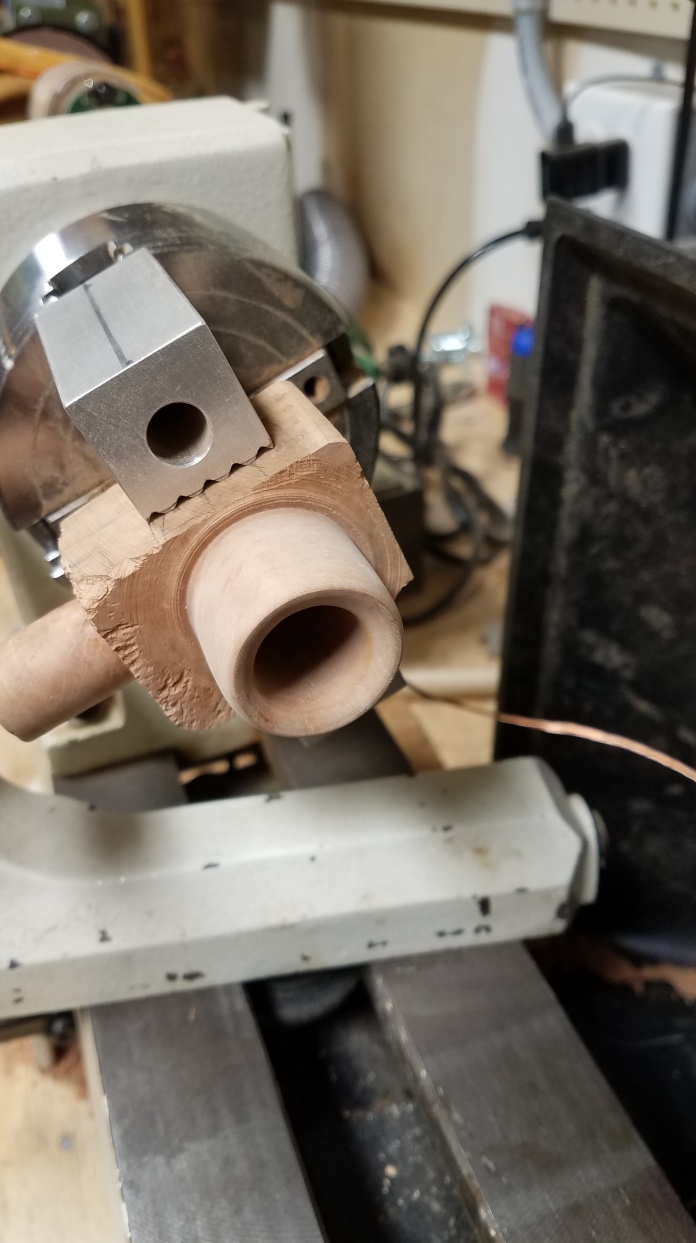

The rest of the restoration was a light bowl topping, sanding, restain and buff. There were a few putty fills I replaced with clear CA glue and Briar chips. There is a large leaf shaped lighter area on the front of the bowl.

I broke the first rule of stem repair in my concentrating on my method of repair. MAKE SURE THE BEND IS CORRECT before doing all the glueing, filing, sanding and buffing. I was working on the pipe separately and didn’t notice my mistake until I assembled the pipe for buffing! Somehow the stem had straightened out way too much!

Too much heat from the heat gun will also soften the CA glue areas and destroy all your efforts at repair! I avoided that by wrapping a damp paper towel on the bit end to lessen the heat damage. With a pipe cleaner inserted, I was able to put the proper bend in the stem with no further damage to the repair area.

I’m done for now but I might come back and tweak the bend of the stem just a bit and rework the repaired area AGAIN. Thanks for looking, hope you enjoyed my repair approach.